Towards Our Splash Date

August 2025

We have a target splash date! We’ve been on the hard since April, and I’m excited to have the end of this first stage of refitting Blue Turtle in sight. If all goes well, we’ll be restepping the mast and re-rigging her on 9/10, and then putting her back in the water on the 11th.

Between here and there, we have a lot of work to complete.

I started the week with a small project - installing and properly securing a lee cloth for our settee, arguably the best sea berth on board. I bolted in two folding Wicard pad-eyes fore and aft, and three eyes below the cushion, all secured with dyneema line that would take the force of a fully grown adult body crashing into it if the boat were to heel while underway.

The lee cloth completely disappears under the settee when not in use.

I also setup and tested our new while-on-the-dock cooking appliances: an updated microwave, a small toaster over/air fryer, and a single-burner induction cooktop. The latter I’m especially pleased with, as it will allow us to avoid using up our propane while tied up at the marina, as well as eliminate the large amounts of humidity that using propane results in.

On-dock cooking appliances.

Both can be secured underway when the roll-top on this locker is closed.

Induction burner.

Likely draws too much power to use on anchor unless the generator were running, but it’s fast and doesn’t add heat or humidity to the cabin while at the dock!

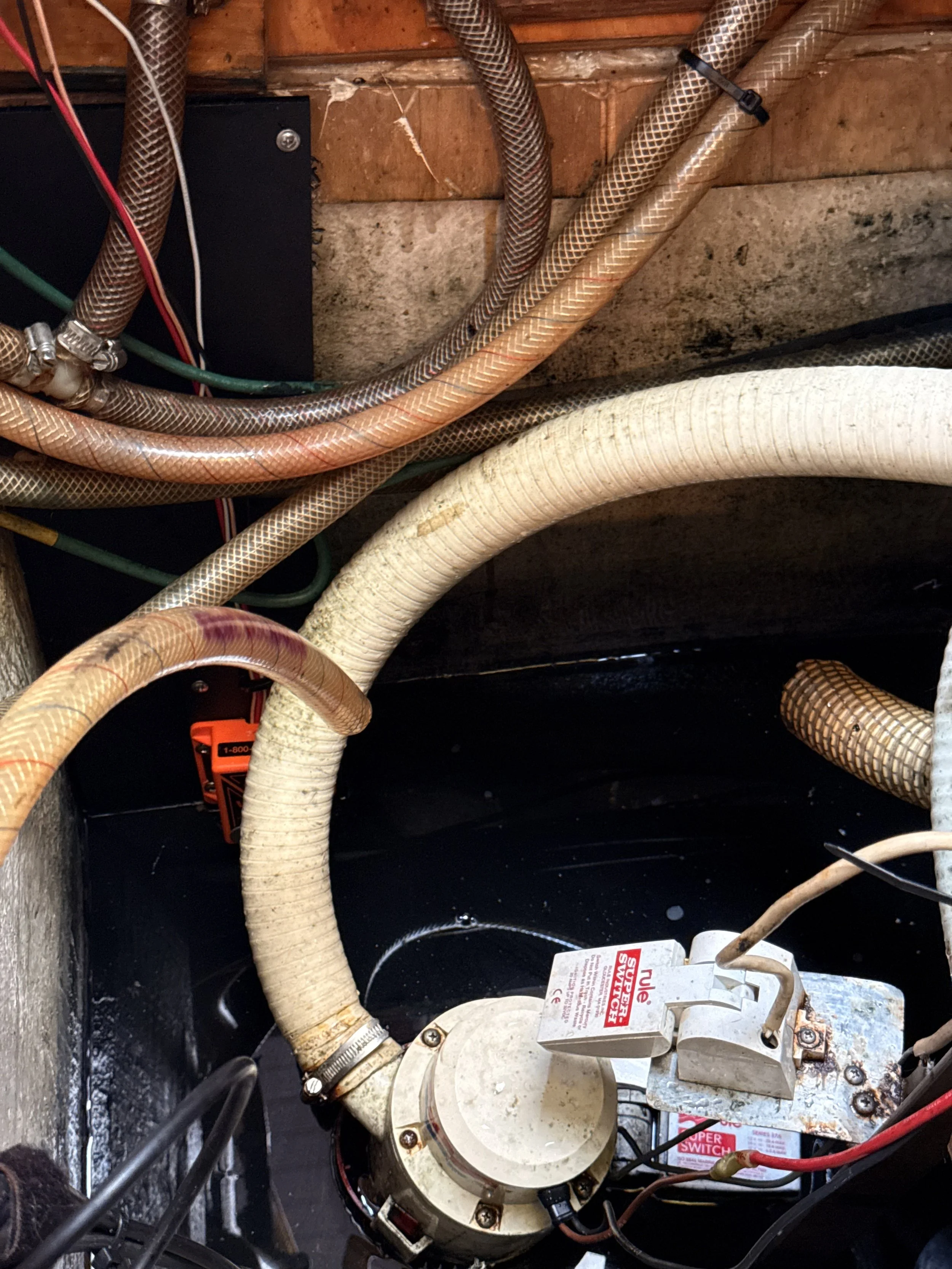

The other in-the-boat job this week was replacing the old solitary bilge pump and mechanical float switch with one of the electric switches purchased from WaterWitch. Unlike a float, electric switches sense water on a small plate, and then energize the bilge pump. I’ve also installed a monitor and control system on our new DC panel, allowing us to see how many times the pump has turned on recently, and also serving as a new high water alarm. Working in the bilge is not pleasant, but after a long and gross day, we have the new switch wired in place. I left the float switches present but with their wires cut; on the off chance the WaterWitch sensors fail, they’ll serve as emergency backups. I still need to install a high water alarm and secondary pump, but we can go back in the water with the same pump setup that Blue Turtle has had for (presumably) years for now.

Upgrading our bilge systems - an unpleasant job!

Along the same lines, I found that the manual bilge pump in the cockpit has a split diaphragm, rendering it inoperable. I’m grateful that Whale continues to provide parts for even their oldest pumps. The one we have appears to be a Whale Gusher 10, likely a Mk2 (a full generation back from the current ones on the market). A manual bilge pump is an essential safety component - I once had my automatic bilge pump burn itself out aboard Wanderer, in rough seas while moving her through Buzzard’s Bay. We ended up pumping every 10 minutes or so, and the recently added pump saved the boat.

The inlet hose also appears to be older, and has no strainer on it, so I’ll be replacing it and adding a proper Jabsco plastic foot before we splash. While at it, I intended to also add a dry bilge pump - a low-flow pump that sits in the lowest part of the bilge, and reaches what the main pumps can't. Stagnant water in a bilge is both unpleasant and not great for the fiberglass, and I’d like to ensure that we minimize it as liveaboards. Doing so will also require adding a couple of new above-the-waterline through-hull fittings, but I believe any seagoing boat should have at least two outlets for their pumps to minimize the risk of a clogged hose at the worst time.

I spent the majority of my past week working in the “back yard” at the marina, where our mast is currently lying on sawhorses. The back yard is not pleasant: it’s exposed and brutally hot, effectively a swamp with all the recent rain, and populated by large red hornets, fire ants, and various biting insects who enthusiastically welcome any fresh meal that wanders into their territory. On the list, however, is replacing all the electronics on the mast - a new tricolor/anchor/strobe light at the top, a new windex and light (which shows where the wind is coming from), a Raymarine anemometer (an instrument that measures wind speed), a new antenna for the updated AIS I’m installing, a brighter steaming lights, and new spreader lights to replace the attractive but hard to use blue ones currently mounted there.

Getting to work in the hot, humid, buggy swamp.

Our mast has two interior wire chases, basically affixed tubes that run the length of the ~60’ spar. I’d initially intended to use the old wiring as a chase, crimping the new wires onto it and then using it to pull them through. On my first attempt to do so, however, the old wire split in the middle. It took a 250’ long electrician’s fish tape and a fair bit of WD-40 to finish the job, but after two days under threat of malaria, I managed to get all the wires pulled through. I’m now waiting on the proper rivets to arrive. Specifically, I’ll be attaching the new hardware with monel blind rivets; monel is an alloy of nickel and copper, and a part made of monel is much less likely to corrode and weld itself to an aluminum mast than a stainless steel screw would.

Finally, our rigger was in town for some other jobs, and while here he and I replaced the lifelines (with properly uncoated steel lines), and rebuilt our two headsail roller-furlers. All of our new rigging is now sitting in our rental’s garage, and presuming the third set of chainplates is properly built, will be installed in early September.

Evan, rebuilding one of our ProFurl furlers.

It was definitely time to do this!.

Before that happens, though, we’re going to be working with our fiberglass guy, Geoff, to repaint the hull. He’s been working to sand down and level things out in advance, filling in years of little dings and cracks. We’re going to repaint her waterline in blue, likely Captain Navy to match the piping on our new cockpit cushions. I’m also looking into having the upper part of the hull above the rubrail painted to match, which would add some additional blue highlights to her. An example from another CSY 44 being sold on YachtWorld:

I think the blue would really pop for us.

Finally, I pulled out the new rig last weekend for Terrapin, our little Walker Bay 8 sailing dinghy. Walker Bays are relatively cheap plastic hard dinghies, but with lines that look somewhat like Fatty Knees or Dyer Dhows.

I bought Terrapin from a guy in Pensacola - a 15+ hour day of driving. She was a bit dirty!

A proper Fatty Knees is on my list for the long term, but for now we’re planning to sell the RIB and use Terrapin. I’m looking forward to rowing her (with new bronze oarlocks and pins coming from England!), but we also have an electric outboard. She’ll be slow, but under no risk of puncture from sharp animal claws.

The sailing rig that Walker Bay came with is a toy - it’s an undersized nylon sail that slides on a sleeve over the meat, with no way to reef or drop once under way. We rigged it once, and I added a jam cleat on her transom to make it easier to control, but it was clear that this was not going to allow us to poke around anchorages the way we’d hoped.

Terrapin’s original rig.

We found and bought a much nicer lateen rig from Jim at Sailboats2Go.com, with an upgraded 55 square foot Dacron sail made by Neil Pryde. I’ve been so busy that I haven’t had time to pull it out and rig it yet, but with a rainy Sunday on my hands, I moved from furniture back and got to work. Sadly, we found that we’d been inadvertently sent a 45sqft sail - Jim immediately sent a replacement, which we should get today or tomorrow. Even so, the new setup (new spar, boom, and mast) looks great, and I’m excited to take Terrapin out exploring.

Not quite the right sail, but still…

It’s a daunting amount of work, but the end is distantly in sight, if perhaps still lying hazily on the horizon. After nearly 6 years, we’re finally within a month or so of living aboard full-time!