Putting In (and Taking Out) Holes

August, 2025

We are deep into it now. The salon of the boat is a disaster. The engine is largely disassembled, the exhaust system sitting in the cockpit. There are 10 large holes in the hull, open to the air.

As we round what I hope is the final corner on the on-the-hard portion of the refit, I’ve convinced the yard (albeit at some cost) to agree to help me fully remove and replace all of the below-the-waterline through hull fittings. For those of you reading who aren’t boaters or sailors, these are effectively holes with ball-valves on them, as you might see under your bathroom or kitchen sink, which allow seawater to come into or out of the boat safely.'

On Blue Turtle, this is how water is taken in (a) to provide cooling to the engine and generator, (b) routed through the air conditioners (which exchange heat via sea water, rather than in the air as you might have in a residential unit), (c) provided to the refrigerator for the same sort of heat exchange, and (d) where it leaves the boat from the sinks and cockpit drains.

We also have additional drains that allow discharge from the bilge pumps, the holding tanks, and one to allow the salinated “rejected” water from the watermaker to go overboard. Originally, our boat also used raw (sea) water to flush the toilets, and there were through hulls dedicated to each head. We also had a mysterious through hull beneath the air conditioner pumps, capped off but left in place.

Through hulls are serious business. A 2” hole below the waterline will admit somewhere around 2,500 gallons of water per hour. Even a large bilge pump rated for 2,000gph will, after accounting for head loss (reduction in pressure as water flows through a pipe), only move 1400gph assuming a 3’ rise. We’re probably seeing even more static pressure on Blue Turtle given the distance to the discharge, so for safely I’d assume ours can do 1000gph or so. In other words, a failed through hull can and will sink your boat. I once read a statistic that for every 1 boat that sinks offshore, 4 will sink at their docks, and 80% of those are due to failed underwater through hull fittings.

Since we’re on the hard already, and given our lack of knowledge as to when these were last serviced, I decided that we’d sleep better if we knew that all of them were new, properly installed, and easily accessible. I also wanted to remove the unknown capped one in the engine compartment, as well as the two head intakes, since the boat has been converted to using fresh water.

The yard at BLM does not allow below-the-waterline work, so this past week was spent with their (excellent) mechanic Gary on board, helping disconnect and in some cases cut out the original bronze through hulls and valves. By Friday afternoon, with a lot of grime, sweat, and blood behind us, we had all of the primary ones out. Our fiberglass expert (Geoffrey from SML Boatworks) began building fiberglass plugs to fill in the holes from the removed fittings, while also working to continue repainting our hull.

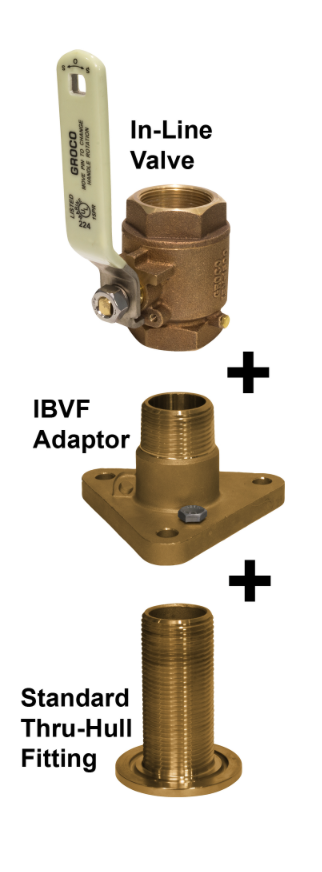

I ordered new bronze fittings from Groco - I opted for their IBVF line, which consists of a standard through hull, a flanged adapter, and a standard valve. The advantage here is that the adapter has NPS (straight) threads for the through hull, and NPT (tapered) threads for the valve, eliminating any mismatch and making future valve/seacock replacements easy.

While working on this, we removed the old air conditioner pumps, and I have two magnetic pumps waiting to go in - far more reliable than the originals. We also discovered the likely reason for why the AC hasn’t been working - the through hull was full of barnacles!

While all of this was going on, Geoffrey also begin the first coats of new paint for Blue Turtle, replacing the (likely 20-ish year old?) Awlgrip that was previously on her. We found that Petit’s “Hatteras Off White” epoxy paint was a very close match to the exiting Awlgrip, which makes future touch-ups very easy! I also opted to have the bootstripe redone, and co-designed a matching section above the rubrail. While the tape is still on and the work is still in progress, we’re really excited for the changes.

We plan to redo her name and hailing port using stencils and matching paint, and at some point will likely add a custom turtle to her stern, perhaps wrapping on the hull. I’m especially pleased with how well the blue picks up the inlaid scrollwork on the trailboards!

Finally, I removed the old freshwater pump in the galley, which provides pressurized water to the sinks and showers, and installed a variable-speed pump in its place. These pumps have soft-starting motors, and ramp up as pressure drops, ensuring a consistent stream of water without any banging, knocking, or light-dimming - all things we had with the old pump. I also removed the residential water filter (a Culligan whole-house filter, I think?), and will be installing a Sea Gull IV filter with all new hose, ensuring we have safe water to drink, cook, and brush our teeth with.