Into the Yard!

Early April, 2025

After a few days at home working on packing and preparing for the coming move, I flew back down to GA. I was renting a car this time, and my mission was to prepare and then move the boat into the marina’s boatyard, followed by helping my rigger Evan with unstepping the mast.

While she was on the hard, the yard had also agreed to take her in and assist with the below-the-waterline work - installing a new prop, and sanding and repainting her bottom.

Once I was back in town, I tackled some small projects, the most significant of which was to finally remove what I believe to have been the original Seaward Princess gas stove in the galley. I intended to replace it with a modern Dickinson Mediterranean stove, which I’d had on board for weeks, largely sitting in the way in the main salon. Not only was the original stove no longer working well, it was also old enough to not have modern safety features.

Getting the original stove out was a nightmare. Once I’d disconnected the propane, I was confronted with old, seized gimbals (which allow the stove to remain level even as the boat heels over underway). Stout bronze rods, I ended up needing to take a reciprocating saw to them, as they were so old as to be utterly frozen into the stove itself.

Disassembling and cutting out the old stove.

It took some doing, but once the gimbals were out, I managed to haul the old stove out of the boat alone. This thing was heavy, and while I like to think that I am still fairly strong, years of boxing, aikido, and jiu-jitsu have taken a toll. With one fully torn and one surgically repaired rotator cuff, my ability to deadlift an awkwardly shaped 100lb+ piece of steel overhead and out of the companionway was questionable, but stubbornness won out and I managed to get the damned thing onto the dock and up to the road.

The new Dickinson wasn’t much lighter, but since Brenton had helped me move it into the boat before the St. Mary’s Debacle, I got it in place and hooked up much more easily. It would still need to be gimbaled at some point, but it immediately improved the galley’s appearance and utility.

New stove installed!

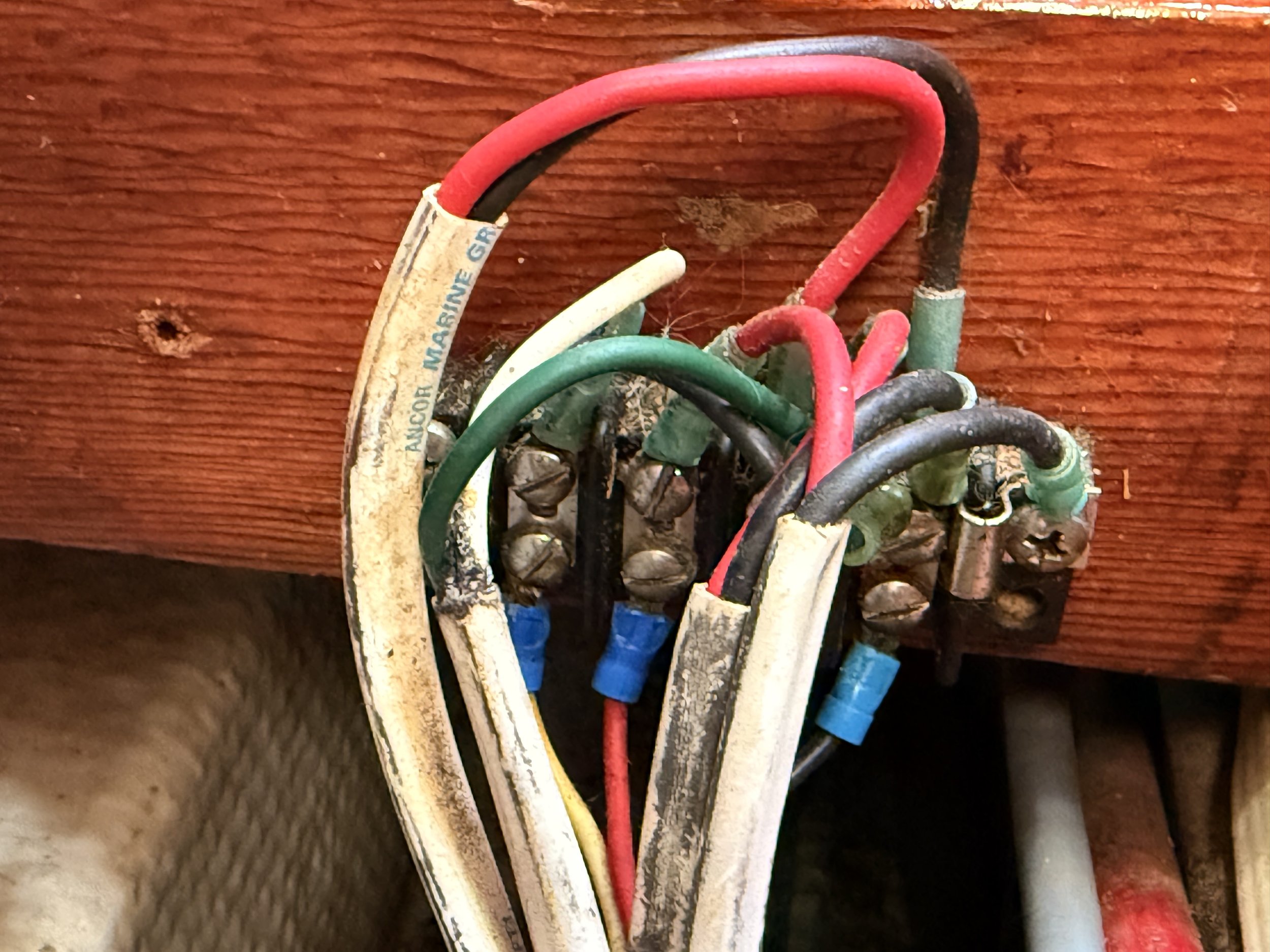

I also got to work on identifying, labeling, and disconnecting the mast wires, all of which ran to a dual busbar that looked like it was from the early 2000s. Replacing the mast instruments is on the to-do list before we go back into the water, and I added a note to also replace the busbar with a proper, ABYC-compliant covered setup as well.

Yeesh.

Early on Friday morning, Don (business partner of Jamie, and who had helped me replace the steering cables) came on board to help me with the move. In hindsight, it was not the best day for it - the wind was blowing 16kts out of the N/NE, and the yard’s travel lift was on the North side of the marina and required me to back her in, with a narrow (especially at anything other than the peak of high tide) channel in which to execute a standing turn.

With her full keel, she does not like backing up, and gets squirrelly after a boat length or so.

We made it down, but getting her spun around was a nightmare with the wind. Every time I’d reach the midpoint of the turn, the wind would catch the bow and try to blow us towards the docked boats nearby, and we had to fend ourselves off. I made two attempts and then gave up, steering her in bow-first, and letting the dockhands use lines to spin her in place. A more exciting morning than I’d hoped for, but in the end, we got it done and she was hauled.

In the lift well, in a breeze.

Moving towards the yard.

On the hard.

Evan, my rigger, came that afternoon, and we started preparing her for the mast to be unstepped the next morning, when a local crane operator would come by. We disconnected all the lines, and removed the Spar-Tite that sealed the mast / deck penetration.

We met the operator early the next morning, and Evan went up the rig to help guide the crane harness in place while I worked from below to ensure that the wires wouldn’t get caught, and to help guide the mast out. A nerve-racking process ensued as we guided the mast off the boat and onto the dozen sawhorses I’d bought the day before at Lowes, but we successfully got it fully unstepped.

The crane, in position.

I may have held my breath here.

Down and safe.

We’d need to hire a local rigger (Evan lives ~5 hours away!) with a mast cart to move it to the rear storage yard when I came back, but for now the stick was allowed to stay where it was.

We got to work disconnecting the remaining wires and lifelines, and then turned our attention to the chainplates.

With the mast down, the crevice corrosion and rust on them was apparent. There are 3 chainplates on each side (for 8 shrouds - forward and aft lowers, cap shrouds, and intermediates), plus one each for the headstay and backstay shrouds, and one for the staysail. We first removed the forestay and staysail plates, then gradually worked on the forestay. We had to drop the anchor and send Evan into the chain locker to get a pair of vice grips onto the broken topmost bolt, while I stood on a precarious stepladder and reached overhead to remove it.

All of these bolts were hex-head, and water had corroded them enough over the years that the bolt heads sheared off in some places. It was obvious that we’d need to replace them.

That’s not good.

The challenge of the shroud plates was that while they were mostly accessible inside of the boat, their bolts were run under the rub strake and cap rail. Accessing them, if I opted to go with new internal plates, would require destructive drilling into both.

Bronze rubrail cover removed, and evaluating how difficult it would be to get to the lower bolts.

I decided to hit pause and consider my options, as investing in new plates was clearly going to take more thought and effort than I initially imagined. Such is the life with old boats, but our time was running short.

Evan packed up and departed that evening, and I prepared to leave the following morning. We planned to keep the Airbnb I’d rented through mid-May, giving us a temporary home base only a few minutes from the marina, and we’d figure out longer-term housing once we were down in Brunswick full-time. For now, I had a flight home, some serious packing to do, and one more long drive back down south ahead of me.