Adventures in Fuel Lines, Part II

Mid-March, 2025

When we last left off, we had just barely made it back onto the town dock at St. Mary’s, and the engine had cut off underway and refused to restart, leading to a last-ditch but successful docking with no power or sails.

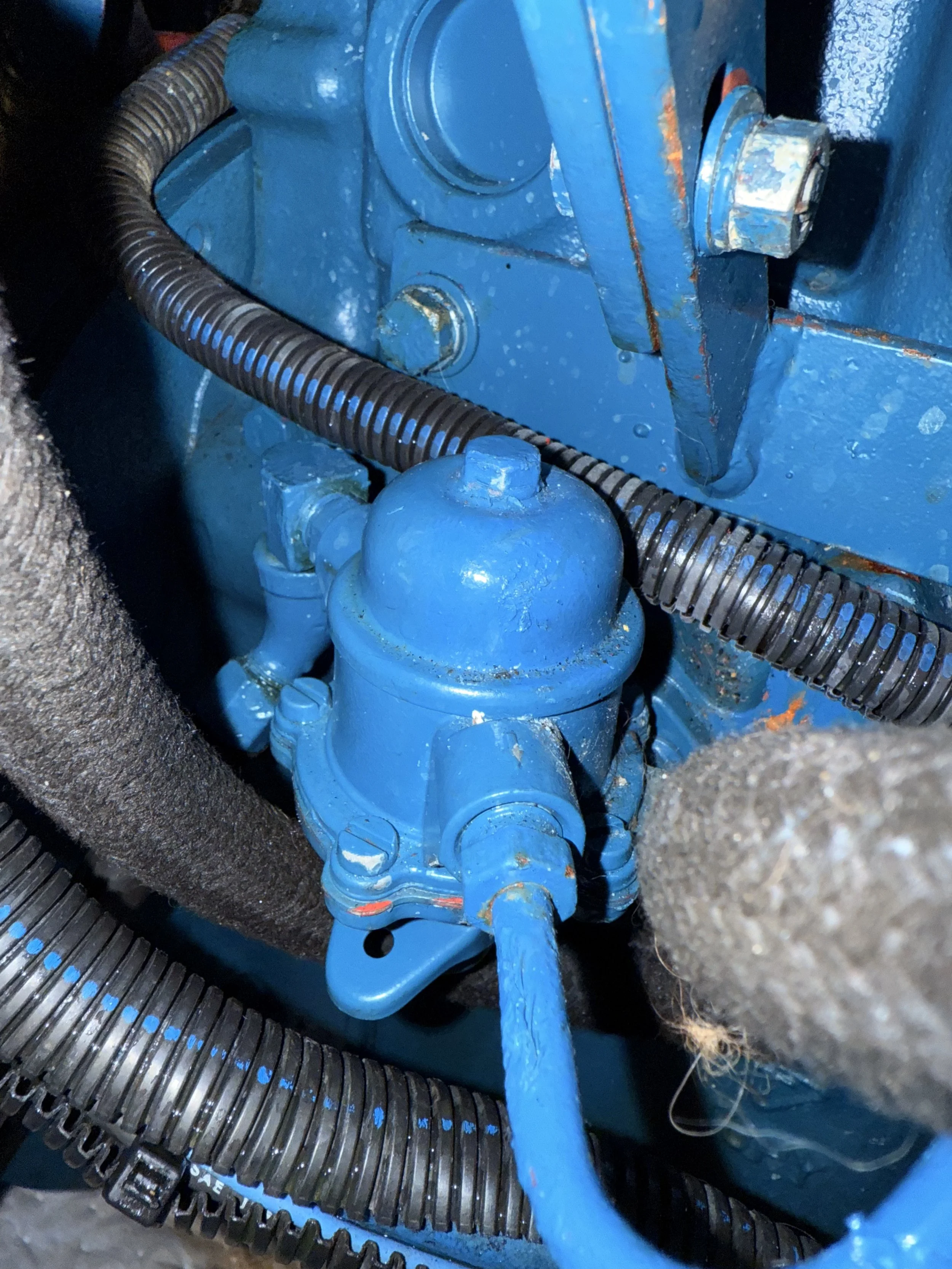

Once tied back up, Brenton and I spent an hour working on the engine, trying to bleed it - first cracking what we thought were the injectors, and then using the manual lift pump to try to remove any air that had gotten in. Bleeding a diesel can be tricky, and Perkins - we have a 4.236, installed in the late 1990s, and rebuilt in 2023 by Kim and Randy - are notoriously difficult. I kept going until the skin on my fingers wore through from the manual pump lever and then admitted defeat, at least temporarily.

My nemesis.

I turned my attention to the weather. According to the dockmaster, a significant system was forecast to come in later in that afternoon, last about 24 hours, through Sunday night. While I had a reasonable complement of fenders aboard, this would be the first weather of any kind I’d be aboard for, with all the typical uncertainties: would the dock lines hold? Were the fenders sufficient? How well backed were the stanchions?

With Brenton and Netaly still with me, we called the local “private taxi” back to the marina up north in Brunswick. A charming woman named Laura drove us, and talked to us about her kids, dogs, St. Marys, and more en route. Once we had wheels again, we drove to the local West Marine and I grabbed a couple more medium fenders.

I also took a note to find a better solution, as locker space aboard was limited, and I wanted to not have these questions again. Moreover, the existing fenders all had felt covers. While they look great, felt can trap sand and grit and wear into the hull.

All fenders set.

Before departing, we drove over to Rocky’s, as I wanted to see the yard in person, and also hopefully meet Rocky. We drove around and I met some of the locals; while the reputation of the place was good, I could see hundreds (if not more) boats in various states of disrepair, and the people seemed rough-and-tumble. There was a single port-a-potty that I could see, and no other facilities. Not ideal, but I figured I could manage.

Following our adventure, Brenton and Netaly departed, and I tucked in for a somewhat noisy and rolly night. I slept well, waking a few times to check lines. Come morning, the boat was covered in kicked up foam, and waves were washing over the docks, but she had held well.

Pinned against the dock in ~20kt winds.

I spent the day working on the engine, digging in to figure out why air had gotten into the fuel lines, and trying to remedy the problem.

I started at the fuel fill hoses, which on Blue Turtle are located in a cockpit locker. Prior to Kim and Randy’s ownership, she was owned by Ralph and Cindy, who lived aboard and cruised her for 25 or so years. There are many thoughtful upgrades, and the fuel system is one.

Blue has two 50g tanks beneath the cockpit sole, and a polishing system in the locker, allowing for transfers between each tank, or recirculating polishing via a Racor dedicated to the cause located just above the tanks. It’s a smart, well designed system that will serve us well when sailing.

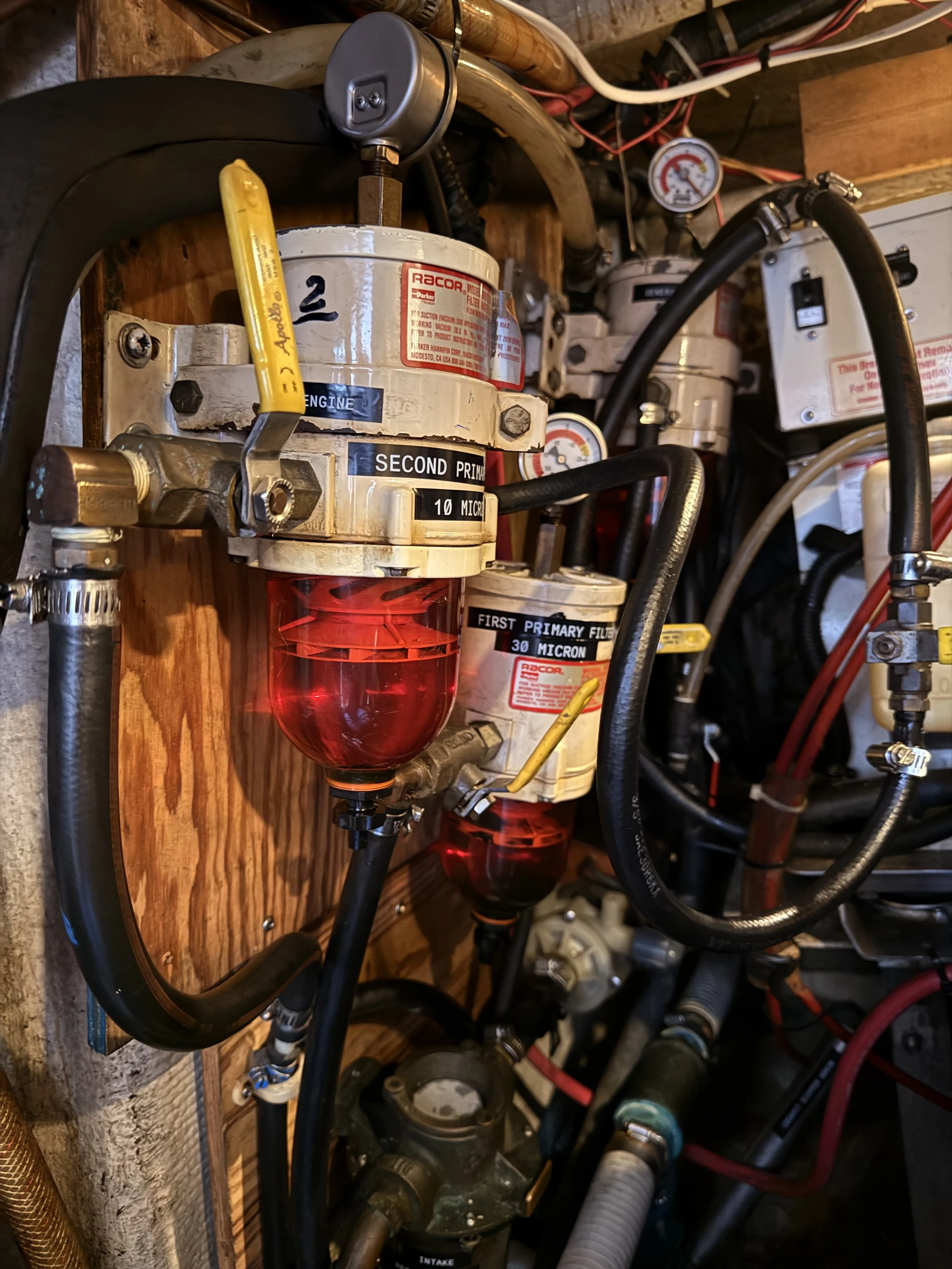

I noticed no issues here, so began tracing the lines back. In the engine compartment, fuel flows into two primary Racor filters, which can be set to both operate in series, or either can be isolated to allow for changing out a clogged filter when underway. I next started looking at these, and discovered a 2µm (micron) filter in the secondary filter, which was where I had been seeing air bubbles when underway.

The Racor filtration setup in the engine room.

2µm is much smaller than is generally needed, and since both of these filters rely on a manual lift pump for pressure, it’s entirely possible that even the slightest amount of clogging could result in back pressure.

Thankfully, there were many spares aboard. I changed the filter out for a 10µm filter, and left the first filter at 30µm. I then pressurized the system using the lift pump, suspecting to find a leak upstream of the second filter - and did, in fact. We had our culprit: a split in the fuel line right before the filter itself.

My nemesis.

I’d have to order new line to change this out, but given the way the Racors were installed, I could isolate the second filter, and run the engine solely on the first. I did so, and then began working on bleeding the engine again, to purge all air from the lines.

After spending a couple of hours trying to no avail to get the engine to turn over, I called a local diesel mechanic, who walked me through bleeding the engine not at the injectors, although I was mistakenly opening the return lines, but at the secondary (on-engine) filter, as well as at the high-pressure injector pump.

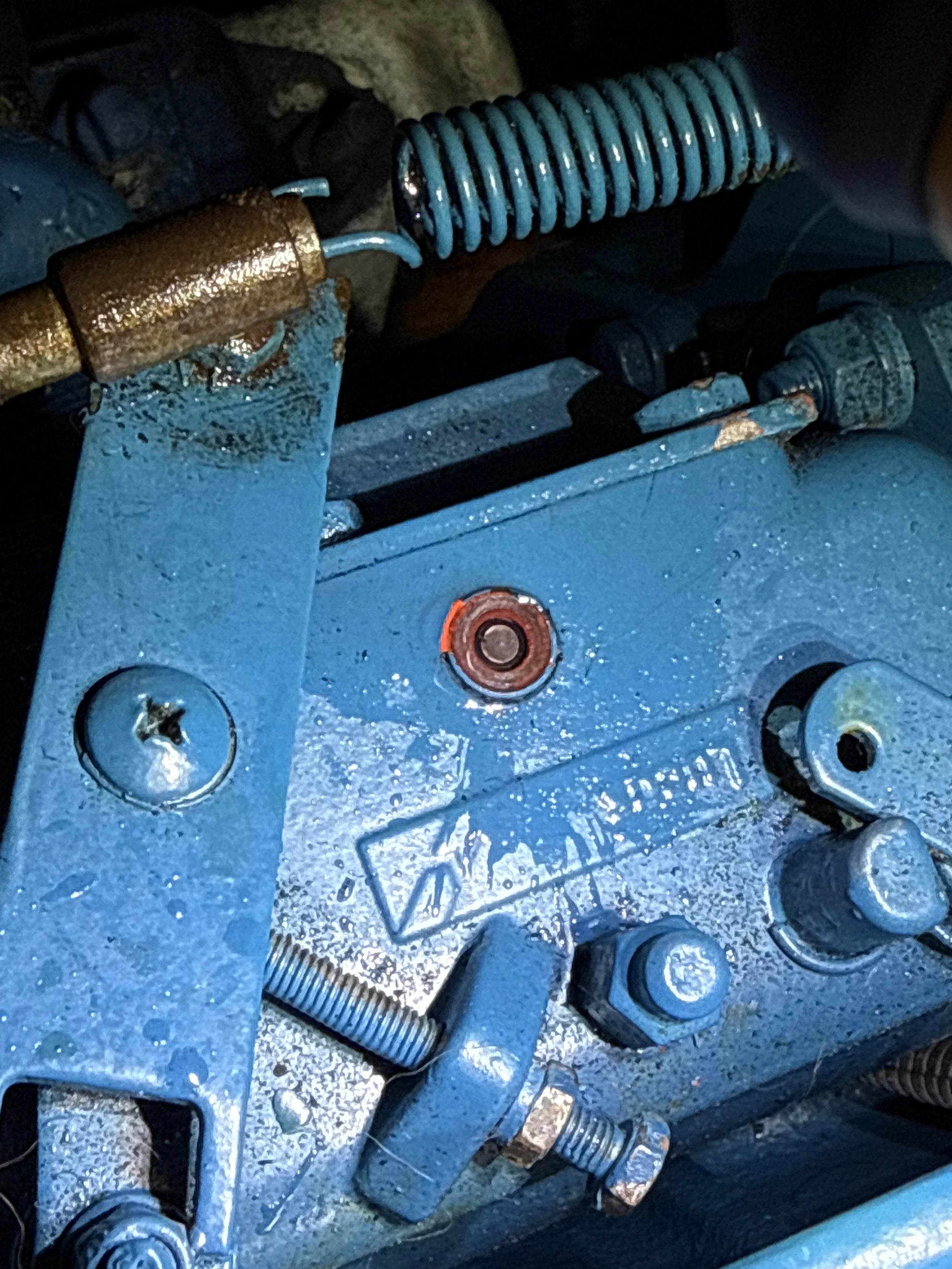

I was easily able to get pressure to the filter, after all my pumping, so I set to work on the injector pump. According to the online diagrams for it, I needed to open a bleeder screw, and then pump until fuel ran through it without bubbles. I grabbed a socket, put it on the bleeder screw, gave it a turn, and then…bang! The nut went flying, and fuel poured out.

Disaster.

I had misread my diagram, and instead of opening the bleeder screw, I had put too much torque on the stud that holds the top cover on the injector pump, and sheared it off. At best, I needed to disassemble the pump and get a new stud. I couldn’t drill it out, because metal shavings would fall into the pump and foul the engine.

I was stuck. I could, from Transatlantic Diesel, order a new pump and send mine in as a core exchange. It would cost around $900 with shipping.

I called the local mechanic back, and to my surprise, he offered an alternative: he had the same pump sitting on a shelf, recently pulled, and could get the matching stud for me. I quickly agreed, and we worked out that he’d come by the next day to help with it. I wouldn’t be able to do the disassembly myself, but I’d accept the lack of learning in exchange for a working engine.

Reassembling the injector pump.

With a bit of time, he had the old broken stud out, and the new one in. We spent the rest of the afternoon working to bleed the engine, with the raw water intake closed so as to not flood the motor. It ultimately took a few squirts of starter fluid to get her to turn over, but by sundown we had the old Perkins rumbling happily again.

Boo, hiss.

I called Brenton, and he agreed to come back up to help me move Blue to Rocky’s, where spinning her into the travel lift would likely require some fancy work with the lines, given how little space or water there was there to maneuver her around. I confirmed with Rocky that we’d arrive that Saturday, a few days away, and in the meantime I would hang out in St. Mary’s, tackle some small projects, and prepare.

Docktails at sundown with some other cruisers who had stopped in at the marina.

Beer at the local brewery.

Dawn on the St. Mary’s River.

Brenton and Netaly arrived on Saturday, early afternoon, and we had scheduled to meet Rocky at 3pm. I called him at 2:15pm, to confirm arrival.

“Sorry, can’t get you in. Someone is using the travel lift to do epoxy work.” (Not what lifts are for, I’d argue, to no avail.)

I explained that I had friends who had driven hours to come help me, that I had a plane ticket for the following day, that we’d been scheduled for a week. None of it mattered; I was told, “sorry it didn’t work out”, although I could “hire a captain” and have the boat moved without me on board, which obviously wasn’t going to be an option.

Frustrated, disappointed, and a little angry, we decided that Blue Turtle would not be going to St. Mary’s Boat Services; the work she needed could be done back in Brunswick, and while it would be more expensive, the yard was far more professional and comfortable. If we left immediately, we’d arrive just after 10pm - and so we set off.

On the way back north, we passed dolphins - always a good sign! - as well as a sailboat that had grounded on a long jetty, awaiting help from SeaTow and taking on water. Sad, and a reminder of how critical it is to know how to read a chart (where the jetty was clearly marked), and not simply rely on autopilot and GPS.

Dolphins off the port bow!

Hard aground.

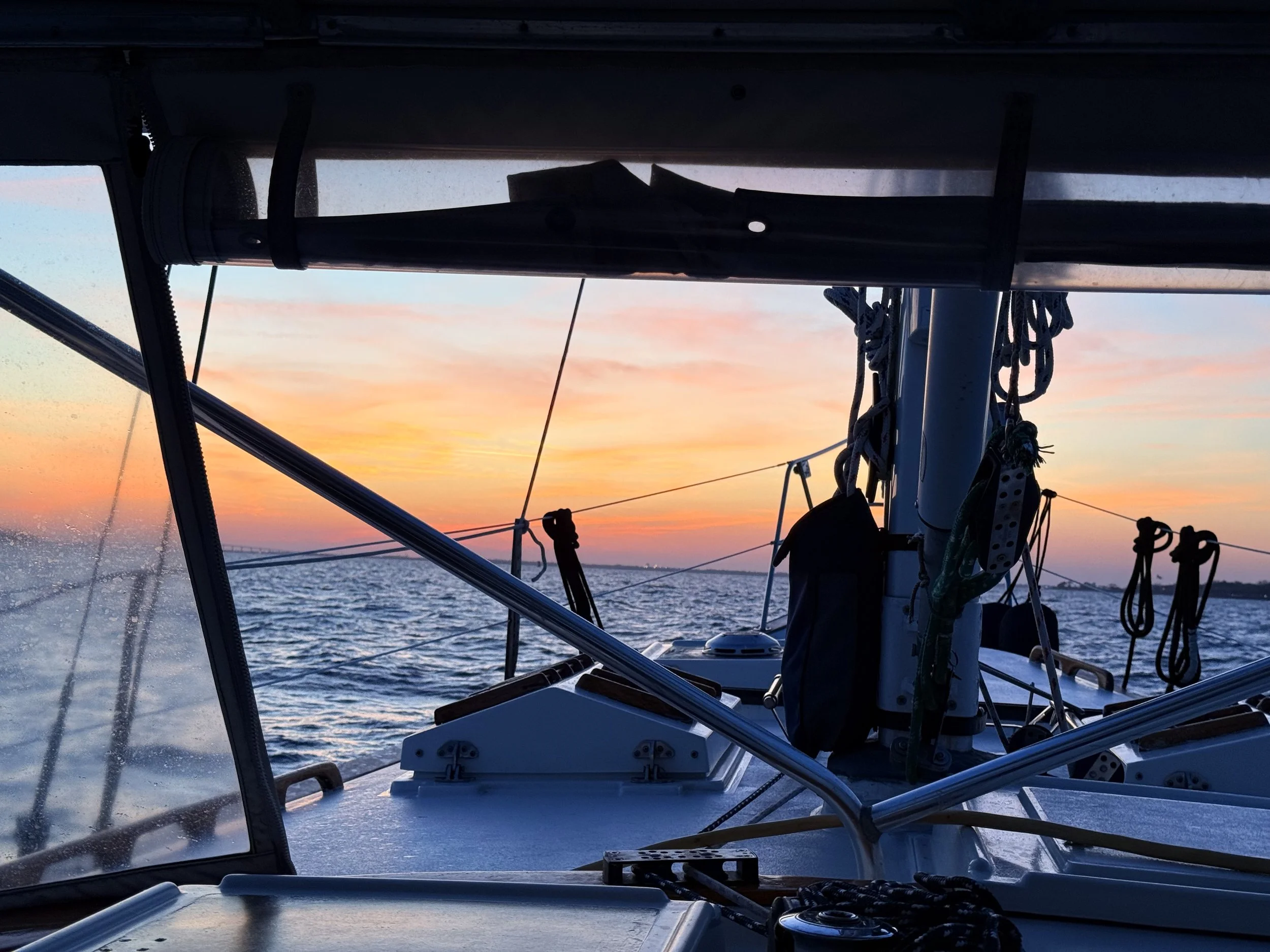

Sunset at sea.

Making way for a very large ship, just under the Sidney Lanier bridge.

We arrived as expected, tied up, and met Netaly (who had driven up to meet us that afternoon) - replete with sushi from a local restaurant. We wolfed it down, had a couple of beers, and turned in.

In the morning, Brenton and Netaly departed for Florida, and I took a Lyft to the airport to head back to RI. I’d need to schedule with the boat yard at the marina to have Blue Turtle hauled, and arrange to have them replace the prop, repaint the bottom, and tackle some suspect through-hull fittings, as no below-the-waterline work was allowed. I’d also have to arrange for a crane to unstep the mast, as I was planning to replace the tangs and standing rigging.

I planned to fly back down alone one more time, to coordinate the haul and initial mast work, and then we’d move down GA “permanently” — until the boat was back in the water — somewhere in mid-April.

I woke at dawn, got in the Lyft, and put a frustrating chapter behind me.